Brochures

CATEGORIES:

Filter:

Filtering by: THERMAL OXIDIZERS

Brochures about: THERMAL OXIDIZERS

Combustion Training

Combustion Training Any Industry, Any Equipment, Anywhere in the World

Read More >>>

North American Shale Market Products and Solutions

Zeeco offers a wide variety of products and solutions for the North American Shale market designed..

Read More >>>

Products & Solutions Sheet

Zeeco engineers, designs, and manufactures advanced combustion and environmental solutions for..

Read More >>>

Propane Dehydrogenation (PDH) Air Heaters

PDH regeneration air heaters must operate reliably through extreme gas velocities, high heat..

Read More >>>

Sulfur Recovery Unit: Combustion Equipment

The Sulfur Recovery Unit (SRU) is often referred to as the Claus Process. This process recovers..

Read More >>>

Direct Fired Air Heater

As a worldwide leader in combustion system solutions, Zeeco is the company to trust for your Direct..

Read More >>>

Halogenated Hydrocarbon Thermal Oxidizer

Halogen-based wastes are an unavoidable reality of the petrochemical and plastics industries. You..

Read More >>>

Nitrogen Bearing Waste: Thermal Oxidizers

Zeeco is the world leader in ultra low-NOx combustion solutions. For decades, our engineers have..

Read More >>>

Packaged Thermal Oxidizers: Gas Processing Applications

Zeeco designs and delivers the most reliable and efficient combustion and environmental solutions..

Read More >>>

Carbon Monoxide (CO) Boiler Thermal Oxidizer

As a worldwide leader in thermal oxidizer solutions, Zeeco is the company to trust for your CO..

Read More >>>

Gas Processing Applications: Thermal Oxidizers

Zeeco is a world leader in thermal oxidizer solutions. For decades, our engineers have..

Read More >>>

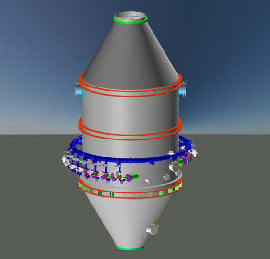

Downfired Salt Thermal Oxidizer

As the global authority in thermal oxidizer solutions, Zeeco is the company to trust for Downfired..

Read More >>>

Sulfur Recovery Unit: Thermal Oxidizer

Thermally treating waste matter is a primary method for disposing hazardous and non-hazardous..

Read More >>>

Turnkey Solutions and Modularized Systems

Whether you’re increasing the capacity of a plant to comply with new regulations, capitalizing on..

Read More >>>

ProFlame+ SRU Flame Scanner

Recovering elemental sulfur, typically through the Claus Process, is a process Zeeco understands...

Read More >>>

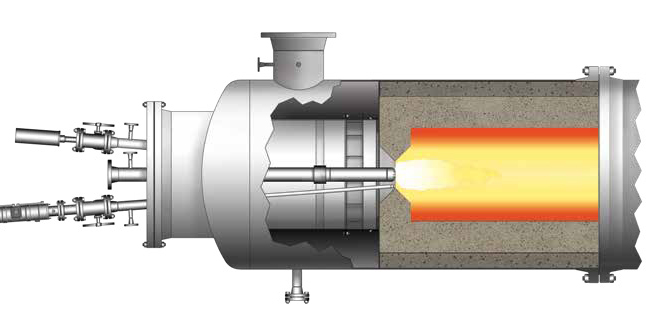

HVW™ HIGH-INTENSITY BURNER HVW Series

The ZEECO® HVW High-Intensity burner is designed to burn acid or toxic gases.

Read More >>>